:car1:

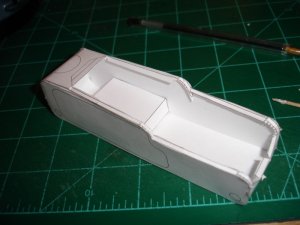

My son asked me to make a pair ofdueling pistols for him and his friends to use as props and I've been readingsome of the posts about design questions so I thought I would start a threaddetailing the model from concept through final product I hope at least some ofyou will find this interesting. Comments and suggestions along the way would begreatly appreciated

My son asked me to make a pair ofdueling pistols for him and his friends to use as props and I've been readingsome of the posts about design questions so I thought I would start a threaddetailing the model from concept through final product I hope at least some ofyou will find this interesting. Comments and suggestions along the way would begreatly appreciated