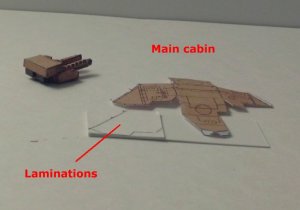

As mentioned in Flarebaffle's thread, I will start a Warhammer section with some of those fabulous models uploaded by Armorman. Eli Patoroch has done a remarkable job in the designing and constructing of those armor vehicles. My first attempt is the Sentinel and by no means will it end there. This Sentinel is about the correct size of the original and it is very well detailed. There where some modifications done like in the foot pads but over all, the model went together rather well. Here are a few pictures of the model and soon I will start a build thread with the color version.

I have placed some of the Warhammer Imperial troops next to the model so you can compare the size and also a Plastic Sentinel so you can compare and see how close to the size and detail is the paper model.

I have placed some of the Warhammer Imperial troops next to the model so you can compare the size and also a Plastic Sentinel so you can compare and see how close to the size and detail is the paper model.